PROTOTYPING

THE ROLE OF VIRTUAL PROTOTYPING

Virtual prototyping, thanks to the evolution of extended reality technologies, is obtaining results that guarantee ever greater efficiency in the value chain of the R&D area of companies, guaranteeing an excellent return on investment. The possibility of using immersive model visualization technologies allows you to create and modify virtual prototypes with greater awareness and reduction of errors to quickly arrive at the creation of the final physical prototype with the lowest cost of materials and production times.

ADVANTAGES FOR CORPORATE COMPETITIVENESS

Considering that any evaluation error, particularly during the initial phases of product development, can translate into an extension of production times, one can imagine how an immersive virtual simulation and prototyping system can immediately highlight any critical issues in order to intervene and make the necessary changes, quickly, first virtually and then in the physical realization process. All this obviously translates into considerable savings in time and costs, generating a rapid return on investment and a significant competitive increase for the company.

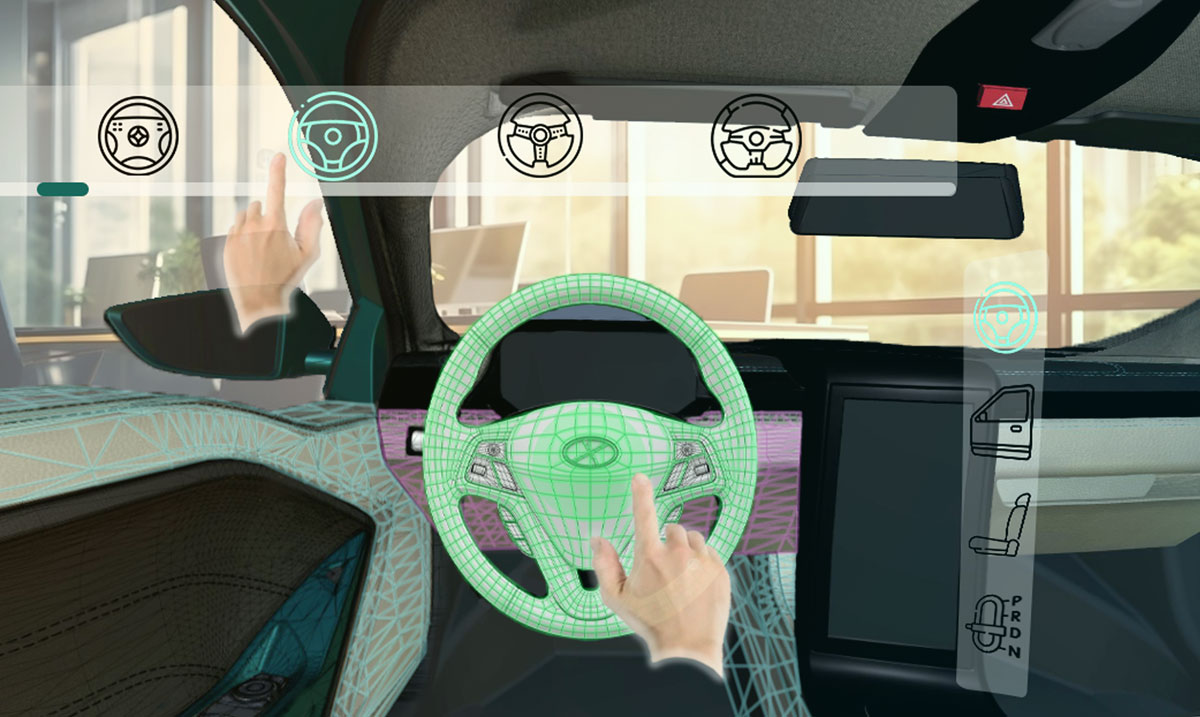

HUMAN CENTRICAL INTERIOR DESIGN

New technologies are a great opportunity but often companies and especially end operators are not yet prepared to assimilate their use. For this reason, Industry 5.0 aims to fill this cognitive gap by making the use of immersive reality increasingly simple and intuitive, for example with gesture recognition functions. Furthermore, the immersive use combined with haptic integration allows you to obtain a clear analysis of the ergonomics of all the product features, suggest optimizations and be able to test the changes made in an extremely short time. Thanks to the use of immersive reality it is possible to interact with the 3D model, the result of the design, to allow customers to verify the pilot "live" firsthand.

Fill out the form and get in touch!

We will contact you as soon as possible.

KEEP IN TOUCH

KEEP IN TOUCH